This is the third instalment in a series about batteries for stand-alone or off-grid power systems. Our first blog in the series provided a rundown on how to size a battery bank, while the second was about the different types of batteries that you will typically find in a remote power system. This time we’ll focus on solar system battery maintenance.

Batteries are the trickiest part of such a system and the part where you are most likely to run into problems. As mentioned previously, wet-cell lead acid batteries are the most typical type of battery that you will find in an off-grid system. Conscientious battery maintenance is essential for the proper functioning, safety, and longevity of your system.

Safety first!

Your battery bank should be located in a secured location to which only authorised people have access, possibly a shed or a closet. The most volatile part of the system with the highest likelihood of causing damage or injury is the battery bank, so safety has to be the highest priority when you handle them. Your installer will inform you of the requirements for ventilation, which is required in the event of gassing (release of flammable gasses) during charging. Signage is also a must, both for safety and legal reasons. The signs will serve as a clear reminder for you regarding how to avoid any mishaps, incidents, or accidents.

Battery log” pre-emptive maintenance

If you have a stand-alone system installed at your home, the most useful thing you can (and should) do is keep a log of whatever you do to the batteries, as well as the other system components. Indeed, keeping a good log of your maintenance may be one of the conditions of your warranty. Your installer should provide you with a logbook with the other paperwork for your system.

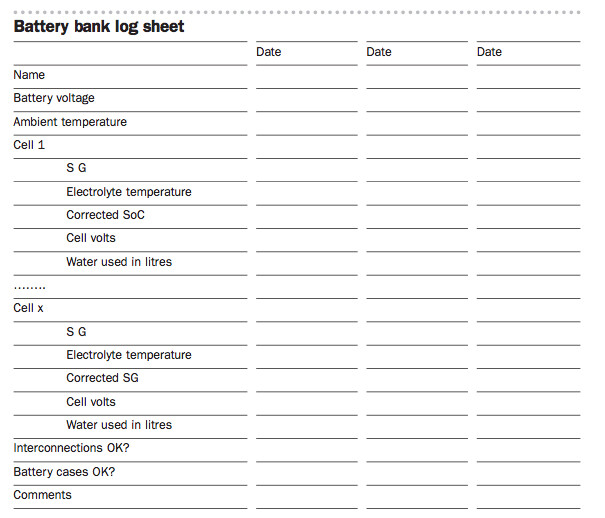

A typical battery maintenance log will look something like the image below. Maintenance should be carried out every quarter or so, about once every 3 months.

Wet-cell batteries require a bit more than valve-regulated batteries in the way of maintenance (see our previous entry on types of solar power system batteries). Valve-regulated batteries are designed to require less maintenance (a luxury whose desirability is reflected in the price), but well-maintained wet-cell batteries can have longer lives. The main difference is that wet-cell batteries are, well, wet, and the water from the water-electrolyte mix can evaporate and may need to be topped up occasionally, whereas valve-regulated batteries are enclosed and don’t require topping up.

Voltage

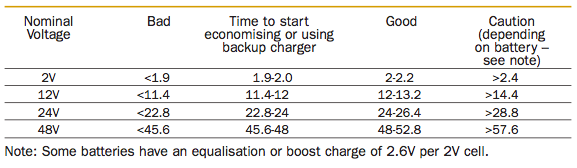

For safety reasons, you’ll need to switch off and isolate your battery bank before you perform the voltage check and specific gravity check. You should carry out a voltage check with a volt meter, first measuring the voltage for the whole system, and then once again for each cell in your battery bank. You’ll thank yourself for keeping a record of the voltage measurements should anything go wrong with your system in the future. The voltage of a system varies, but individual cells are typically 2v. The following chart is a rough guide for when to be concerned about your battery bank or individual cells. If any one cell is more or less than 10 % of the average voltage for the system, the system should be equalised (see below) and the voltages rechecked.

Specific Gravity

Maintenance also calls for regular reading and recording of the specific gravity (SG) of each cell of your battery bank, usually during the ˜float’ stage of the charging process (at which point, if all is functioning properly, your battery is fully charged). The specific gravity is an indicator of battery charge, and keeping a good record of this will help identify the cause of any future problems that you could run into. To measure the SG you’ll need a hydrometer, which essentially looks like a baster that you’d use to redistribute the juices when baking a chicken or turkey. You’ll also need a glass bulb thermometer, as SG fluctuates with the temperature of the electrolyte. Specifications vary depending on the battery manufacturer, but your SG should be 1.250 at 25°C.

Corrected State of Charge

Since your batteries may not be at 25°C when you measure the SG, you’ll use a correction factor, the temperature and the SG to produce a number that is indicative of the actual state of charge (SoC) of your batteries, referred to as the Corrected SoC. The correction factor and the specifics of how to do this calculation should be provided by your installer. Even if you don’t or can’t get around to doing it, though, it is important to at least record the SG reading and the temperature so that it can be calculated after the fact.

Battery cases and interconnections

Whenever you check your batteries, you’ll also need to check the interconnections between cells and the cases of the cells to make sure that there aren’t any faulty connections between cells, cracks in the cases, or corrosion on the terminals.

Occasional equalization

Wet cell batteries occasionally require an equalisation charge to ensure that all the cells in the bank are at a similar charge. This ensures the optimal functioning of your battery bank and, like all the maintenance procedures mentioned in this blog, acts to head off any potential problems before they happen. For the specifics of equalisation charge rates, it’s best to consult your installer or your owner’s manual. Likewise, the frequency of equalisation may vary from 7 to 28, or even up to 90 days, all depending on the specifications of your system.

Written by:

James Martin

Master of Environmental Management, UNSW

Solar Energy Analyst

Source and Resources:

Image Credits:

The charts in this blog were also taken from Latrobe’s guide.

- Solar Hot Water System: Everything You Need to Know - 27 February, 2024

- Enphase Battery: An Independent Review by Solar Choice - 20 January, 2024

- Can I add more panels to my existing solar system? - 8 August, 2023

Good afternoon sir please my question is that , in a dusty area how often should the PV panel be clean ? And secondly what is the effects of dirty PV panel ?

Thanks

Hi Tajudeen,

Thank you for your comment. There is no set amount of times that a solar system needs to be cleaned. If you are situated in a high dust area I would suggest a few times a year so maybe every 3-4 months.

If the dust builds up, over time there will be a loss of efficiency in the system but it can depend on how heavy the layering is. It will be best to speak with an installer regarding these area as they will be able to advise on maintenance issues.