Phinergy, an Israeli battery technology start-up, and aluminium producer, Alcoa, have recently revealed a prototype electric car with a 1,100-mile driving range that is powered by Phinergy aluminium-based metal-air battery technology.

The key to the dramatic improvement in range lies in a hybrid battery system, which consists of a primary battery made of lithium-ion (used during short trips) and Phinergy’s proprietary aluminium-air battery that acts as a range-extending battery for long hauls.

The resulting 1,100-mile driving range represents a four-fold improvement over the market-leading Tesla Model S, which has a range of only 300 miles per charge. The video below shows Phinergy’s prototype car in action.

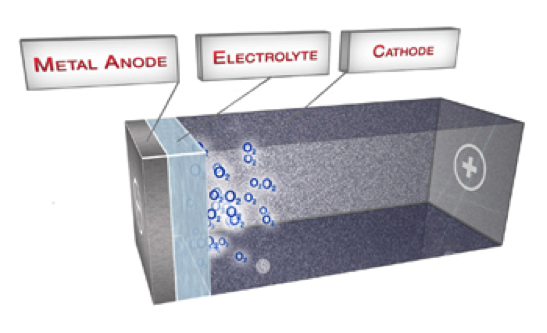

Conventional batteries such as lithium-ion are closed systems and require the battery’s cathode to be engineered not just to undergo chemical reactions itself but also to hold sufficient quantities of a reactant (typically oxygen), which is required for reactions at the metal anode to release energy.

Structure of a conventional battery (Image Credit: Phinergy)

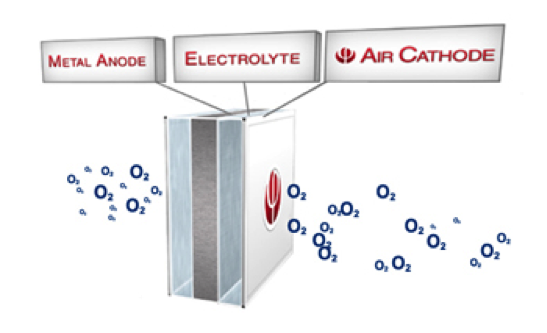

In contrast, Phinergy’s metal-air battery aims to dramatically shrink the size and cost of cathodes by replacing the closed system (shown above) with an open, ‘breathable’ system with an ‘air cathode’ (shown below), which uses oxygen from the surrounding air instead of bound oxygen in the cathode for the energy-generating anode reaction.

Structure of a metal-air battery (Image Credit: Phinergy)

Given that cathodes are the most expensive and the bulkiest components of a conventional battery (can be up to 70% of the total weight of the battery), the cost savings from cheaper cathodes can be quite significant. KAir, a small start-up funded by the US Department of Energy, for example, has recently claimed that it’s potassium-air batteries are upto 78% cheaper than other closed-system battery technologies from established players like Ambri.

However, what has held back the adoption of such batteries is the short life-spans of air-electrodes. Phinergy’s crucial innovation has been in designing an air-electrode that manages to filter out CO2, which is the major contributor to battery degradation. While specific details about the cycle-life of the batteries are scarce, the company claims that the air electrode lasts for thousands of operating hours.

Moreover, the anode of Phinergy’s battery is made of aluminium, which is not only readily recyclable, but can also be switched out easily when depleted. Although not as important for other applications such as energy storage, quick recharging makes Phinergy’s battery a lucrative alternative to conventional batteries for electric car applications, where customer demands for quick charging/’re-fuelling’ methods are a major consideration.

Phinergy is currently entering pilot production in conjunction with aluminium producer Alcoa and is aiming to keep production costs low by manufacturing its aluminium-air batteries in Alcoa’s facilities in Canada, which has abundant low-cost hydro-electric power.

The approach seems to have worked well for Phinergy, which is currently in talks with automotive manufacturer, Renault-Nissan, to supply aluminium-air batteries for Renault’s new electric car line to be introduced in 2017.

The development is no doubt significant for the electric car market, but also offers promise for cheaper and higher density batteries for other applications such as grid/renewables energy storage. In fact, Phinergy is currently developing a long-lasting zinc-air battery targeted towards energy storage applications.

Although its zinc-air battery is expected to have even higher energy densities compared to its automotive aluminium-air batteries, Phinergy may face stiffer competition in the energy storage market, where the range of competing battery technologies is less constricted by the need for fast recharging.

Even in the metal-air battery space, Phinergy faces direct competition from established start-ups like KAir and Fluidic Energy, the latter of which already has commercially-available zinc-air batteries in production.

Nevertheless, the promise of metal-air batteries is clear and this latest development is significant not just for the electric car industry but also for the renewables sector as cheaper batteries can make large-scale energy storage more profitable, reducing one of the key barriers to solar and wind adoption today.

Top Image Credit: Phinergy

© 2014 Solar Choice Pty Ltd

- Future of Utilities – Part 1: The death of base-load generators - 11 September, 2014

- Sharp enters energy storage market with SmartStorage - 18 August, 2014

- Phinergy extends electric car range with metal-air battery technology - 13 August, 2014