Australia’s solar boom is entering a new chapter, and as early residential systems reach the end of their lives or are being retired early to make way for newer, more […]

Solar Panel Recycling in Australia: A Guide for Homeowners and Installers

Australia’s solar boom is entering a new chapter, and as early residential systems reach the end of their lives or are being retired early to make way for newer, more […]

Can Smart EV Chargers Power the Future Grid? In this episode of the EV Charging Podcast, we sit down with Stefan Grosjean, the founder and Group CEO of Smappee. Grosjean […]

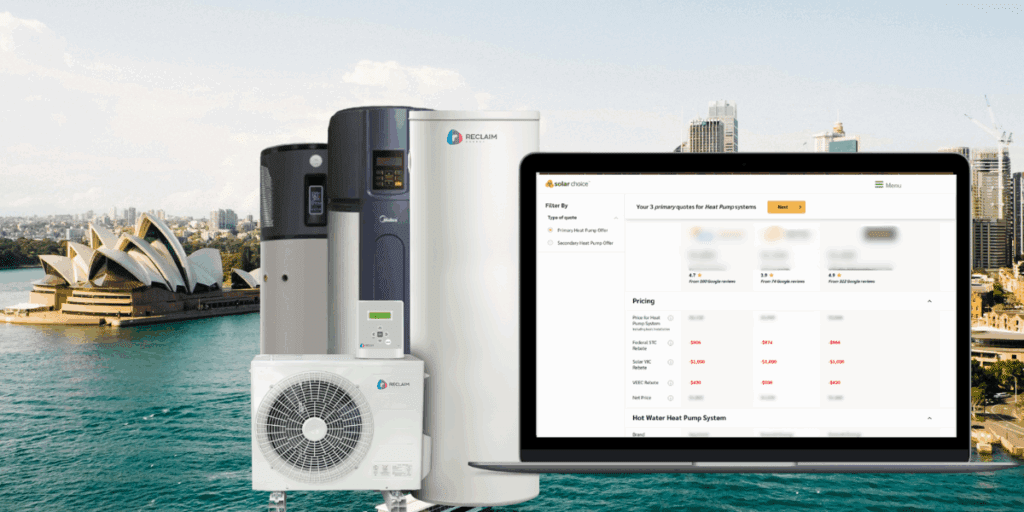

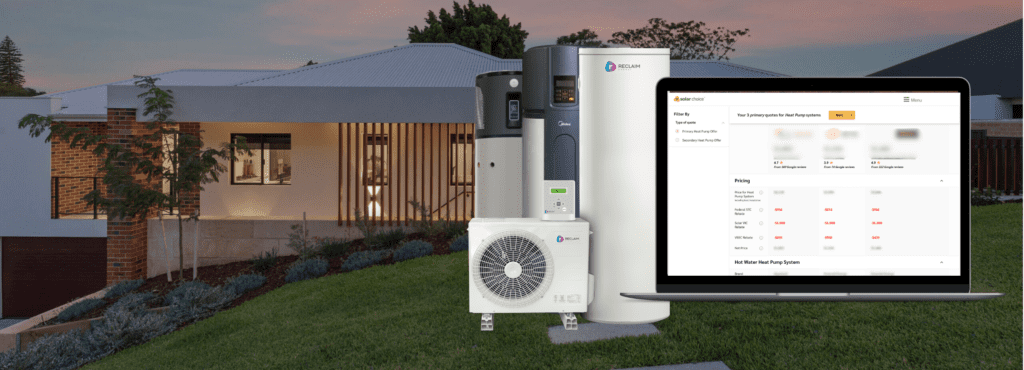

At Solar Choice, our mission is to provide homeowners in Sydney and across NSW with clear, impartial advice on energy-efficient hot water solutions. We don’t sell or install heat pumps. […]

Note: This Best EV Chargers in Australia comparison is 100% independent. Solar Choice is not affiliated with any EV charger brand or installer, and we receive no financial incentives to […]

Note: In compiling the list for the best heat pump hot water systems in Australia it’s important to remember that Solar Choice is not associated with any heat pump installer […]

If your EV charger isn’t working properly—whether it’s charging slowly, flashing error codes, or tripping your circuit—don’t panic. This guide to EV charger troubleshooting covers the most common home charging […]

Looking to install an electric vehicle charger at home, in an apartment building, or for your business? This 2025 guide to EV charger rebates and incentives in Australia covers everything […]

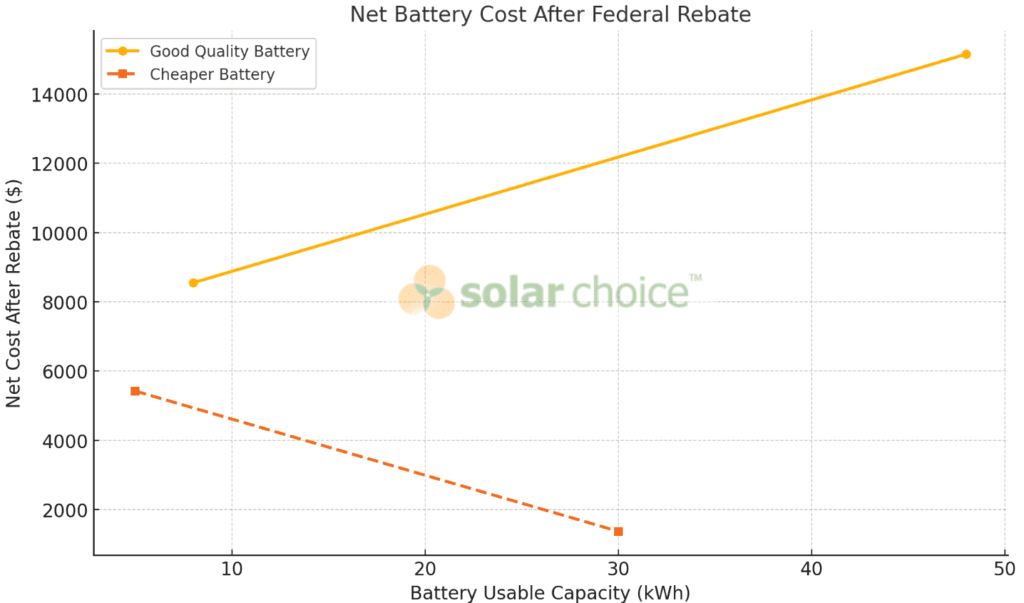

The government has announced a federal battery rebate that comes into effect on the 1st of July, although many eligible installations have already taken place. The battery rebate offers customers […]

Compare solar and battery quotes online now NSW Home Battery Incentive 2025: What You Need to Know From 1 July 2025, the NSW Government introduced a new battery incentive for […]

The WA Government’s Battery Rebate Scheme is now officially open. Eligible households can access up to $3,800 in rebates and $10,000 interest-free loans to install home batteries, helping reduce power […]

Spotify SoundCloud Amazon Music Deezer iHeartRadio Pocket Casts Podcast Addict Apple Podcasts YouTube The EV Charging podcast explores the journeys of founders and leaders of EV charging organisations in the […]

Spotify SoundCloud Amazon Music Deezer iHeartRadio Pocket Casts Podcast Addict Apple Podcasts YouTube How a UK-Born EV Charger Became a Solar Hero in Australia In this episode of the EV […]

The Australian federal governments solar battery rebate, the “Cheaper Home Batteries Program” has officially begun as of the 1st July 2025. It offers an upfront discount of around 30% of […]

Solar Choice has a pre-vetted network of over 40 electric vehicle charger installers who have uploaded their price, product and warranty information into our database for our quote comparison service. […]

Based on our network of over 40 installers across Australia, we publish the average prices for heat pump hot water systems with a breakdown for each state. Solar Choice has […]

The Solar Choice Price Index measures the cost of solar power systems on a dollar per watt ($/W) basis. This pricing metric helps consumers and industry stakeholders understand the average […]

As more Aussies make the switch to electric vehicles, the demand for flexible charging options is kicking into high gear. Sure, home wallboxes are great—if you always charge in the […]

Commercial EV chargers are no longer a future consideration — they’re here, and they’re multiplying fast. For businesses aiming to meet sustainability targets, it’s more than just a trend to […]

The body corporate at Aris Apartments in Newstead, Brisbane engaged Solar Choice to complete a solar and EV charging feasibility study for their 55 unit residential apartment building. The feasibility […]

Previous Episode Next Episode Key Takeaways Level 1 EV chargers are often dismissed as too slow—but for many apartment dwellers in Australia, they might be the smartest and most practical […]

Previous Episode Next Episode Key Takeaways Level 2 EV chargers are becoming a go-to solution for electric vehicle owners across Australia—but are they the right fit for your apartment building? […]

Previous Episode Next Episode Key Takeaways If you’re living in an apartment and considering EV charging, Level 1 chargers might be the overlooked solution you’ve been searching for. Commonly referred […]

Solar batteries are a major investment. Whether you’re installing one with a new solar system or retrofitting batteries to an existing solar setup, it’s essential to understand what protects that […]

As Australians look to cut power bills, protect against blackouts, and store clean energy, solar battery storage systems have never been more popular. But with dozens of options on the […]

Are Solar Batteries Safe? Yes — solar batteries are generally safe when installed correctly by Clean Energy Council (CEC) accredited professionals. Australian standards ensure systems are built and installed to […]

ACT’s Interest-Free Battery Loan Explained As part of its commitment to net zero emissions by 2045, the ACT Government offers an innovative support program to help residents invest in clean […]

As energy costs rise and feed-in tariffs fall, solar batteries are becoming a smart upgrade for Australian homes. This definitive 2025 guide will help you understand solar battery storage—how it […]

In Victoria, consumers have the luxury of applying three different rebates to reduce the upfront cost of installing a heat pump hot water system. Through the federal government a heat […]

The great news for NSW customers is that there are 2 governments rebates that are available for customers looking to upgrade their hot water system to an energy-efficient heat pump […]

Last year the number of heat pump hot water systems installed in Australia increased by 70%. The rise of this technology has been linked with improvements in performance, the ability […]

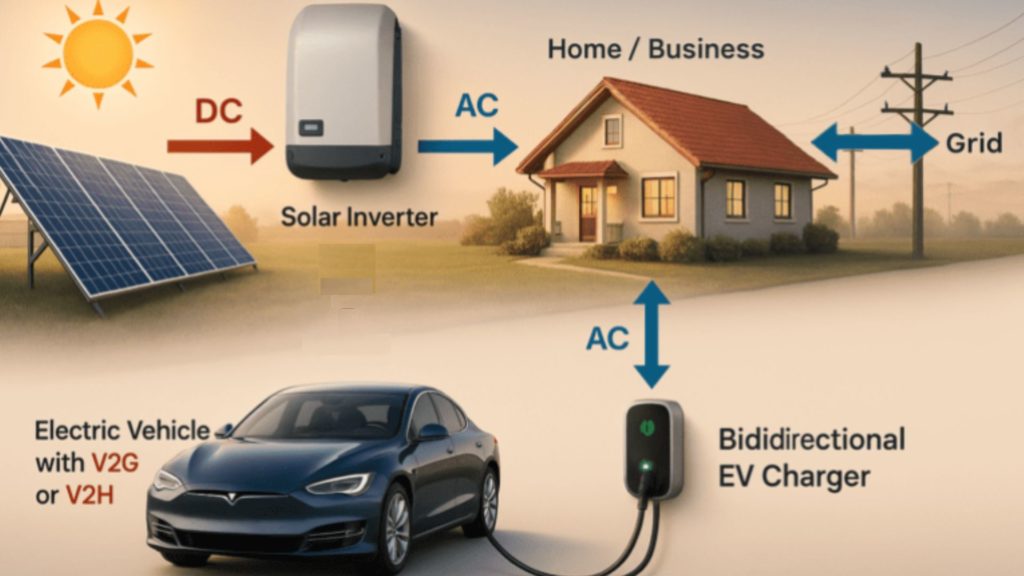

Bidirectional EV chargers promise to play an important role not only for electric vehicle (EV) owners but for Australia’s evolving energy landscape, with the potential to do more than just […]