Dyesol is positioning itself to revolutionise the solar photovoltaics (PV) industry by making available an innovative but still largely uncommercialised PV technology: the Dye Solar Cell (DSC). DSC is a 3rd generation solar PV technology that uses a ‘sandwich’ of materials to mimic the photosynthetic process of plants in order to create electricity from sunlight. It has numerous applications, including Building-Integrated Photovoltaics (BIPV) and portable PV.

Non silicon-based solar power?

Silicon PV cell structure and the photovoltaic effect. (Image: Creative Commons via Wikipedia.)

Conventional solar PV

Although dominated by conventional silicon-based solar panels, there are also a number of non-silicon solar PV technologies (usually used in thin-film PV) available on the market, but most function in a way similar to silicon-based modules: light strikes a semiconductor substrate with contains a positive-negative (p-n) junction, and electrons are jostled into moving through it, then flowing into an electroconductive material (such as aluminium) to produce harnessable DC electricity.

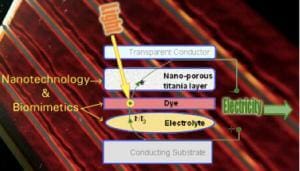

DSC Solar Cell Technology Diagram (Image Via Dyesol)

Dyesol’s Dye-based solar PV

DSC technology, on the other hand, in the place of a dense film or substrate semiconductor, incorporates a triple layer of nano-particulate titania (Titanium Dioxide, used as a pigment in paints and, rather oddly, toothpaste), a long-life dye, and an electrolyte. The first layer is a nanotechnology material, while the latter two work to emulate the natural photosynthetic process that occurs in the leaves of plants. The end result is that sunlight is converted into electricity as opposed to being trapped in sugars, as happens in plants. The ‘bread’ of Dyesol’s material sandwich takes the form of two electroconductive materials–one transparent on the light-facing surface, and another acting as a substrate behind the cell. These lead the electricity out of the cell to whatever its end use may be.

Key Advantages of Dyesol solar PV technologies

-Simpler production processes mean lower cost than conventional silicon-based PV technologies, as well as lower embodied energy in manufacture

-Can be applied like a film to the surface of a number of different substrates, including conventional building materials

-Can replace conventional glass panels and windows in buildings instead of taking up roof space

-Can be produced in a variety of different colours, for flexibility in building design

-Produces electricity even in low-light, real world conditions including cloudy and hazy days, dappled lights, dawn and dusk

-Avoids the use of expensive raw materials and has no toxic emissions

-In 2008 saw peak conversion efficiencies of up to 11% (sunlight to electricity) in laboratory conditions (comparable or greater than peak efficiencies for many other thin-film solar PV materials)

To whom are Dyesol materials and technology available?

Dyesol’s DSC materials are available for purchase in the Dyesol online shop for academics and others learning about the technology. Concurrently, Dyesol is working with key multinational companies to bring DSC integrated products to the mass market in a variety of applications, including in steel roofing and glass windows. Projects are currently underway with Tata Steel, one of the world’s largest steel producers and with Pilkington North America, one of the world’s largest glass makers. Dyesol is a truly global company with headquarters, laboratory and engineering facilities in Queanbeyan, NSW (recently visited by Australian PM Julia Gillard) and operations in Italy, the UK, Japan, and South Korea, among other countries.

Dyesol’s bold vision: grid price parity in the UK

At least for the near-term future, it seems that conventional solar PV modules are likely to remain the most readily available and cost-effective option for roof-top retrofit residential solar installations. Meanwhile, however, Dysol is pushing the envelope in its efforts to commercialise DSC, and in a joint demonstration project with Tata Steel in the UK, has made an explicit goal of ensuring that the electricity produced by its modules is competitive with that produced by the electrical grid, thereby eliminating reliance on the UK’s feed-in tariff for economic viability.

This is an impressive goal, especially considering that most solar PV installation companies in the UK are trying to come to grips with the recent, premature slashing of these very government incentives–many forecasting a kind of solar Armageddon. Should Dyesol achieve its goal, there will likely be repercussions for the entire solar PV industry. As the whole point of subsidisation of renewables is to enable competitiveness with fossil fuel generation, solar electricity at grid prices could completely transform the way that solar PV is seen as a renewable energy source, and possibly even shape the future trajectory of subsidisation for solar PV–doubtless much to the ire of Dyesol’s competitors.

© 2011 Solar Choice Pty Ltd

- Solar Power Wagga Wagga, NSW – Compare outputs, returns and installers - 13 March, 2025

- Monocrystalline vs Polycrystalline Solar Panels: Busting Myths - 11 November, 2024

- Solar Hot Water System: Everything You Need to Know - 27 February, 2024

.

A well written article on where Dyesol are at the beginning of 2012.

By 2013 TATA-Dyesol “Solar Steel” should be around 10% efficient in 1/3 sunlight which Dyesol now prefer to use for comparing DSC against other Solar Panels.

There have been several good efficiency steps forward in 2011 with Dyesol’s Research Partners NIMS , CSIRO and Merck.

Maybe Dyesol needs to stop calling DSC “Solar” as it works in any light . ie Photon Roof or Photosyntheses Glass