A number of changes to the Australian standard for solar photovoltaic (PV) installation standard AS/NZS 5033 came into effect from 16 July 2012, with a 3 month grace period for installers to get acquainted with them. The alterations were decided on by the EL-042 Standards Committee, on which the Clean Energy Council (CEC) sits alongside representatives of other stakeholders as electrical safety bodies, fire brigade representatives, training organisations, and related industry bodies.

What are the July 2012 AS5033 changes about?

The changes to AS5033 relate to wiring, labeling, disconnection devices, earthing, and system documentation and commissioning. In addition to these alterations, the standard also now includes a number of new definitions that are indicative of the future direction of the industry, such as ‘AC module’, and ‘Micro inverter’. These technologies are still relatively new on the Australian and global markets, but could become a common alternative to the ‘centralised inverter’ style of system that comprises the vast majority of the market.

Interestingly (and relatedly), one of the major changes–the requirement to use heavy-duty conduit around all DC wiring–will raise the difficulty level of the installation of conventional, centralised inverter systems. This change will have virtually no effect on the installation of AC solar systems to the same degree, as the DC wiring in such systems is significantly shorter.

The July 2012 AS5033 standard changes are outlined below. The following can also be downloaded in pdf format here. The same document can be found on the Clean Energy Council’s Solar Accreditation website.

AS/NZS 5033 – Changes

General

– Modules in the same string shall be installed in the same orientation (clause 2.1.5) -Domestic voltage rating of installation limited to 600 Volts DC (Clause 3.1) -Greater than 600 Volts DC requires restricted access to all installed equipment (Clause 3.1)

– Change of safety class, from Class II to Class I, for PV module insulation system rating, (clause 1.4.1.1) earthing is required of all exposed metal module frames and mounting rails. (AS/NZS 3000 1.4.27)

–All equipment and wiring shall be selected and installed in accordance with the provisions of AS/NZS 3000 and the requirements of this Standard. (Clause 4.1)

o Please Note: Inverters must be installed in locations with safe access and adequate working space and be readily available (this does not apply to micro inverters)

Wiring

All PV wiring and components must be fit for purpose and installed to minimize exposure to detrimental environmental effects (clause 4.1) and are protected from abrasion, tension, compression & cutting forces. They need to be routed, supported and protected in accordance with AS/NZS 3000. (Clause 4.3.6.3)

-PV array cabling is to double insulate (Clause 3.2) and be flexible (multi strand) to allow for movement. (Clause 4.3.6.2)

-Needs to meet PV1-F specification and be tinned copper to reduce degradation of the cable over time. (Clause 4.3.6.2) TPS cable is not permitted.

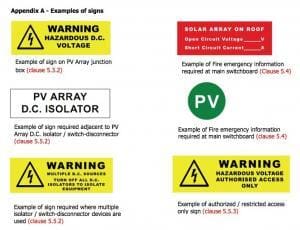

-PV cabling must be identified with a permanent, indelible marking in English or coloured “SOLAR” labels attached at intervals of not less than 2 metres. When the PV cable is enclosed in conduit or other wiring enclosure a coloured “SOLAR” label must be attached at each end of the wiring enclosure and at each change of direction (clause 5.3.1)

-The solar array to inverter solar DC cables within buildings shall be in heavy duty conduit. (Clause 4.3.6.3.2)

-All outdoor equipment must be suitable for the environment and be at least IP 54 and UV resistant. (Clause 4.3.3.1)

-If exposed to the environment, cabling shall be UV resistant or protected from UV by installation in UV resistant conduit marked with “T”. (Clauses 4.3.6.2 and 4.3.6.3)

-When installed on roofs or floors must be mechanically protected (in enclosures or conduit) and not obstruct natural water drain paths or promote accumulation of debris. (Clause 4.3.6.3)

-Are protected from abrasion, tension, compression & cutting forces. (Clause 4.3.6.3) CEC| AS/NZS 5033 – Changes | July 2012-Plastic cable ties are not to be used as a primary means of support. (Clause 4.3.6.3)

-Ensure wiring in enclosures and cable entries maintain the IP rating and are sealed to manufactures specifications and double insulation between conductors is maintained and installed in such a way as to minimize strain on the connectors. (Clause 4.4.4.4)

-Connectors are mated with connectors of the same type from the same manufacturer. (Clause 4.3.7)

-String fuses in PV arrays are rated for DC (Clause 4.3.1) and are rated to interrupt fault currents from the PV arrays. (Clause 4.3.4)

-Fuse holders shall have a current rating equal or greater than the corresponding fuse and provide protection suitable for the location. (Clause 4.3.9.1)

Disconnection devices

-An isolating / disconnection device shall be installed at the array if the PCE is more than 3 metres from the array (clause 4.4.1.4)

-An isolating / disconnection device shall be installed adjacent to the PCE (clause 4.4.1.4) -Disconnection devices will be not be polarity sensitive and must operate in all active conductors.

(Clause 4.3.5.2)

-If Circuit breakers are used they are not be polarity sensitive. They must also be rated to interrupt the full load when operated and have a voltage rating greater than VOC. (clauses 4.3.1 & 4.3.4)

-Must be certified to AS/NZ 60898 or IEC 60947. (Clause 4.3.5.2)

-All PV array switch-disconnectors are readily available (Clause 4.4.1.4) and are to be marked with an identification name or number according to the PV array wiring diagram. They shall have a clear indication of isolation position “off” and “on” e.g. O and I. (Clause 5.5.1)

-When the PCE has an internal means to isolate the solar array this switch-disconnector shall be mechanically interlocked so that it will isolate the array if repair or replaceable of a module is to be carried out within the PCE. (clause 4.4.1.2)

-Where multiple disconnection devices are installed they are either ganged so that they all operate simultaneously, or grouped in a common location with a warning sign indicating the need to operate all switch-disconnectors to isolate the equipment (clause 4.4.1.3).

Earthing

PV module and mounting frame earth connections are to be a purpose-made fitting providing earthing or bonding connections or purpose-made penetrating washers or equivalent between the PV modules and mounting frame for the connection of dissimilar metals purpose-made fittings are installed to manufacturer’s instructions (clause 4.4.2.2).

-Cable lugs, earthing termination and bonding cables are to be fixed by stainless steel bolts, washers and penetrating washers to aluminium frames (clause 4.4.2.2)

-Earthing or bonding connections MUST BE arranged so that the removal of a single module earth connection will not affect the continuity of the earthing or bonding connections to any other module (clauses 4.4.2.2 & 4.4.2.3)

-Self-tapping screws cannot be used for earth connections to the PV array framework (clause 4.4.2.2).

PV array functional earthing

Connection to earth is at a single point, connected to the main earthing terminal of the electrical installation. This connection point is between the PV array disconnection device and the PCE and as close as possible to or located inside the PCE (clause 4.4.3.1) the PV system functional earthing conductor has the same rating as the earth fault interrupter EFI (clause 4.4.3.2)

LV PV Arrays with functional earthing

On an earth fault the EFI interrupts the earth fault, shuts the PV system down and provides a fault indication and an external fault alarm (Clause 3.4.2).

SYSTEM DOCUMENTATION and COMMISSIONING

(AS/NZS 5033 5.7 & AS/NZS 4777 7.1-7.3)

-A system user manual will be provided including -A short description of the function and operation of installed equipment -System rating and component ratings,

-Commissioning date and equipment location -A list of equipment supplied – with serial numbers -A list of actions to be taken in the event of an earth fault alarm

-The shutdown and isolation procedure for emergency and maintenance -A system connection diagram -The system performance estimate, including expected seasonal or operational variation

-Recommended maintenance including a maintenance procedure and timetable -Commissioning records and installation checklist -The array frame engineering certificate for wind and mechanical loading

-The installer/designer’s declaration of compliance for wind and mechanical loading -Equipment and workmanship warranties -Equipment manufacturers documentation (data sheets, handbooks, etc.)

-A copy of the Shutdown procedure and any electrical safety warnings

-A procedure for verifying correct system operation and -actions in the case of a system failure

-Contact personnel for installation queries and system support.

Definitions – Clause 1.4 –1.4.2 – A.C. module

A PV module with an A.C. inverter mechanically secured to it so that the electrical output is A.C.

–1.4.3 – A.C. module inverter An inverter mechanically secured to a PV module in such a way that the connection between the module D.C. output and the inverter input is internal to the A.C. module inverter and there are no external D.C. terminals.

–1.4.4 – Available, readily Capable of being reached for inspection, maintenance or repairs without necessitating the dismantling of structural parts, cupboards, benches or the like

–1.4.15 – Equipotential bonding Electrical connections intended to bring exposed conductive parts or extraneous conductive parts to the same or approximately the same potential, but not intended to carry current in normal service.

–1.4.37 – Micro inverter A micro inverter is a small inverter designed to be located adjacent to a PV module so the D.C. cable length is less than one metre. The D.C. connection between the PV module/s and micro inverter is accessible and may be made at installation. The capacity of the micro inverter output is limited to 350 VA and D.C. connection is at ELV and is limited to no more than two PV modules.

–1.4.40 – Power conversion equipment (PCE) An electrical device converting one kind of electrical power from a voltage or current source into another kind of electrical power with respect to voltage, current and frequency. NOTE: Examples include D.C.- A.C. inverters, D.C.- D.C. converters, charge controllers, etc.

–1.4.41 – Power conversion equipment, non-separated Power conversion equipment where there is no electrical separation between the input and output circuits. NOTE: An example of a non-separated PCE is a transformer less (non-isolated) inverter.

–1.4.42 – Power conversion equipment, separated Power conversion equipment where there is at least simple separation between the input and output circuits. NOTE: Separation can be achieved by the use of a transformer with separate windings.

–1.4.61 – Restricted access Access restricted to authorised persons only e.g. by a perimeter fence or barrier with access only via a padlocked or equivalently secured gate or door.

© 2012 Solar Choice Pty Ltd

- Solar Power Wagga Wagga, NSW – Compare outputs, returns and installers - 13 March, 2025

- Monocrystalline vs Polycrystalline Solar Panels: Busting Myths - 11 November, 2024

- Solar Hot Water System: Everything You Need to Know - 27 February, 2024

Since the switchboard in a house is usually internall located Does AS5033 also require PV installation signage to be displayed on the externally viewable electricity meter panel?

Hi Simon,

Best to get in touch with the CEC about that–they should be able to help you out fairly quickly.

its really making things difficult, heavy duty conduit cant believe it,

where is the product range for this as far as i know there is only the black flexy and very expensive let alone difficult to work with.

i would really like to see the cec set a mimimum rate for a solar installer to charge, as i have to increase my prices, while im being told by solar retailers, they wont pay more than $600 for a 1.5kw solar install. some thing is not right here. Two guys, van, materials, equipment, safety gear heghts etc, insurances, tools the list goes on.

i have had two installs inspected and the majority of issues are with the seler of the system, i.e warranties and owners manual not being supplied. the cec should start cracking down on sellers and leave the professionel electricans alone