Pushing the boundary of lithium-based battery technologies is a new lithium-sulphur battery technology being jointly developed by researchers in the US and Korea.

National Institute of Standards and Technology (NIST), University of Arizona and Seoul National University have jointly developed a new and inexpensive method to fabricate lithium-sulphur batteries, which have the potential to replace lithium-ion technology thanks to their high capacity and promising long-term performance.

Although the energy density (or storage capacity) of standard lithium ion batteries have improved over the years, they require bulky cathodes made of complex compounds that are not only energy-intensive (and therefore expensive) to create, but ultimately limit the maximum achievable energy density. In fact, it is largely the breakthroughs in cathode technology that has been pushing Li-ion and other battery technologies forward, making them safer, cheaper and better.

One of these promising Li-ion battery alternatives is the sulphur cathode, which is not only lighter and easier to fabricate than ceramic-based compounds used in typical Li-ion batteries, but also a substantial improvement in the energy density of lithium-ion batteries.

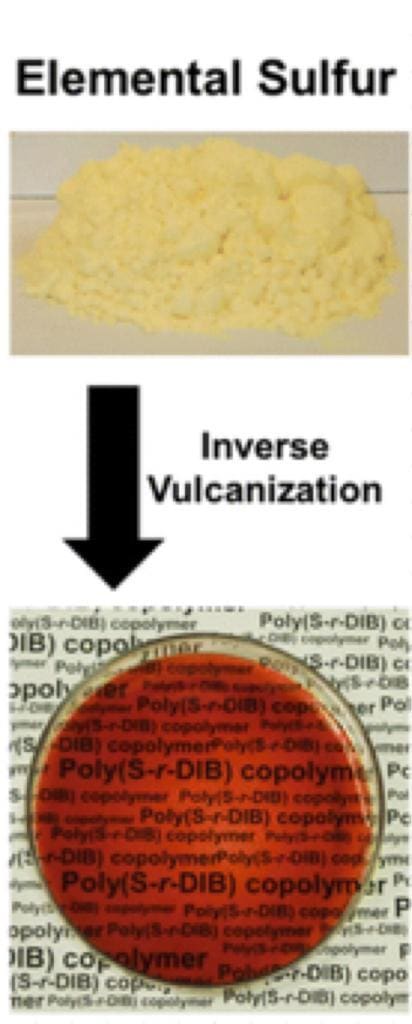

However, sulphur as it exists in its natural, crystalline form (pictured above), easily combines with lithium to form compounds that gum up the battery’s insides. The crystalline compounds can also crack under the stress of repeated cycling. Hence, typical lithium-sulphur battery will lose a significant portion of their charge capacity within a few dozen charge-discharge cycles.

But thanks to a new chemical process, researchers have managed to create a stable, non-crystalline form of sulphur for use in cathode (pictured below). The process used to make the material is similar to the process used to make car tyres in which rubber – a carbon-containing material – is heated with a sprinkling of sulphur to create ‘vulcanised rubber’ – a hardy product. However, by switching the ratios of the two ingredients (a lot of sulphur and a little bit of the carbon-based material) and further optimising the kind of carbon-based materials used, researchers have managed to create a high capacity and stable battery cathode from this “reverse-vulcanisation” process.

The resulting battery was found to retain more than half its initial capacity after 500 cycles – comparable to the kind of performance that standard lithium-ion batteries offer. In fact, according to NIST materials scientist Christopher Soles, “Five hundred cycles with the capacity we’ve shown is definitely better than what’s in your laptop today.”

While such performance has been previously achieved on other lithium-sulphur batteries, such cathodes require more complex manufacturing processes that are not cost-competitive for large-scale manufacturing. What makes this development unique is that the battery has been made from only easily available materials and using moderate heat (185 ˚C), which can be easily achieved even in a baking oven!

Illustrating the simplicity of making the cathode from the raw materials, Jeffery Pyun from the University of Arizona says, “We take it, we melt it in one step and pow, we get this plastic…If you were to come to our lab, we could do this in five minutes.”

However, it is important to note that the batteries are still based on lithium chemistry, which is inherently unstable (Lithium can combust if exposed to air). While this risk has been successfully mitigated in standard Li-ion batteries, this also means the technology will need to undergo rigorous safety testing before it hits the market.

However, given the simplicity of the process and the cost of the raw materials (sulphur is considered to be a waste by-product from petroleum processing), the technology has the potential to unlock the benefits of lithium-sulphur batteries and replace Li-ion.

© 2014 Solar Choice Pty Ltd

- Future of Utilities – Part 1: The death of base-load generators - 11 September, 2014

- Sharp enters energy storage market with SmartStorage - 18 August, 2014

- Phinergy extends electric car range with metal-air battery technology - 13 August, 2014