Researchers at Stanford University have developed an innovative way of producing ‘solar cell stickers’, thin-film PV devices which can be adhered onto practically any backing material.

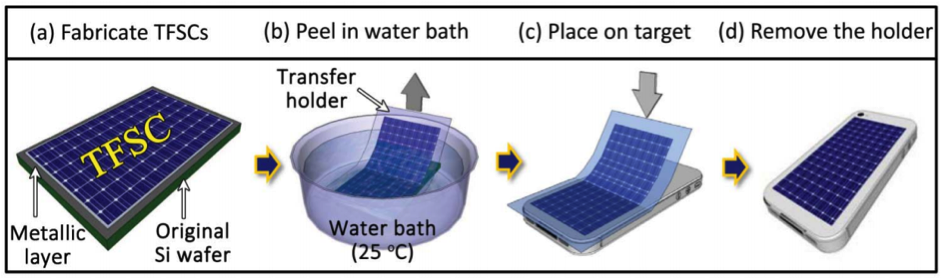

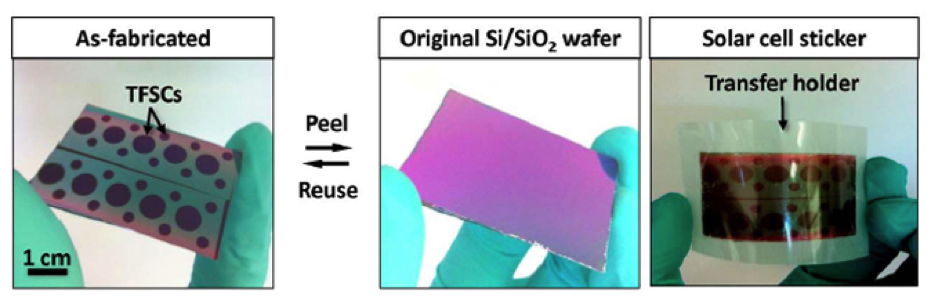

The thin film solar cells are assembled on top of a silicon wafer substrate and covered with a protective polymer film and thermal release tape, which acts as a carrier for the transfer of the cell onto a new substrate. In between the thin-film solar cell and silicon wafer lies a thin nickel layer – attached to the rear of the thin film solar cell – and a layer of silicon dioxide which is in contact with the silicon wafer. The nickel acts as a buffer layer which allows for the separation of the thin-film solar cell from the substrate when submerged in room-temperature water.

When the solar cell is complete, it is simply submerged and peeled off by hand. The separation of the thin-film solar cell is enabled as the water seeps in between the silicon dioxide and nickel layer allowing the two materials to break apart. The cell can then be applied to any surface with the use of double-sided tape or other adhesives.

The fabrication process for solar cell stickers. (Image Credit: Nature)

These solar cell stickers are currently at a proof-of-concept stage – the reported efficiencies of the devices have been made on cell areas no larger than 0.28cm2 and are processed by hand in a lab environment. A focus of the research going forward is to develop ways of producing large area solar cell stickers which can be fabricated and peeled off with automated processing, in a manner suitable for high volume manufacturing. In addition, the demonstrated solar cell sticker efficiencies of 5.2–7.6% have room for improvement when compared to leading thin-film solar cell devices.

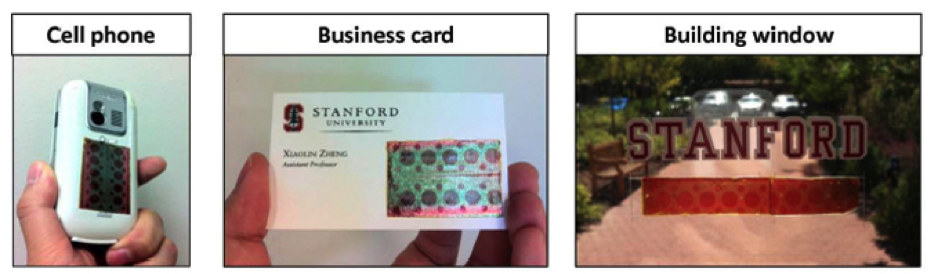

Solar cell stickers can be applied to all types of rigid surface. (Image Credit: Stanford University)

This innovation extends the range of solar cell applications – virtually any exposed surface is a target. For example in BIPV applications, solar cell stickers could be retrofitted onto roofs, walls and even windows. Every surface of a building exposed to sunlight can potentially produce energy. As depicted above, portable electronics and other small objects such as business cards, bags and clothing may also be equipped with the devices. Solar cells stickers break down barriers to accessing solar energy and will allow everyday people to install PV with just a flick of the wrist.

Top Image Credit: Stanford University

© 2014 Solar Choice Pty Ltd