“Do people think that crystalline silicon technology headed the way of the dinosaurs?” This is a question that SunPower co-founder Dr Dick Swanson asked the audience at the 40th annual Photovoltaic Specialists Conference (PVSC) this year. With crystalline silicon cells coming into mass production at the beginning of this century for the first time, costs have fallen substantially. Meanwhile, there has also been a flood of research funding for new thin film materials and third-generation solar cells.

UNSW’s Dr. Zhao Jianhua has achieved new efficiency records for crystalline silicon cells consistently for 15 consecutive years, but could the technology soon be reaching a ceiling? There are people who harbour such doubts, but by the end of PVSC 2014, my belief was that the world will be looking at crystalline silicon PV with new eyes.

While the dinosaur metaphor is a stretch, crystalline silicon cells are indeed the oldest PV technology that has been put into practical use. 60 years ago, on 25 April 1954, Bell Labs announced the first practical solar cell product, “The Bell Solar Battery”, which was based on crystalline silicon. For his role in the creation of this invention, PVSC’s organizing committee awarded the Special Contribution award to Dr Morton Prince, thanking him as “a true pioneer in the photovoltaic industry” who has shown incredible dedication and enthusiasm for the cause of PV research.

Morton Prince receives the Special Contribution award at PVSC 2014

Although silicon solar cell efficiencies have improved continuously over the 60 years since the invention of the Bell Solar Battery, the use of crystalline silicon–a relatively expensive material to produce–has often been questioned. As thin-film PV technologies have gained prominence, chatter about when thin-film’s efficiencies would overtake those of crystalline silicon has become common. But although thin-film cells do have their undeniable advantages, it seems that people have come to accept the fact that they will not replace crystalline silicon anytime soon.

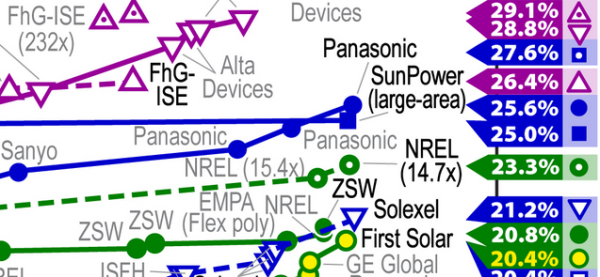

In the last ten years, as per the United States National Energy Laboratory (NREL)’s PV technology efficiency table (below), most PV technologies have consistently broken their own records; besides crystalline silicon, these technologies include thin-film (amorphous) silicon, CIGS, CdTe, GaAs, multi-junction cells and dye-sensitized technology, and–more recently–perovskite materials. But crystalline cell efficiencies reliably serve as the industry benchmark that these competitors all aim to surpass. Crystalline silicon cells have kept ahead of the curve thanks to new production methods and cell design features that are being brought from the laboratory to the production line.

Explorations in the field of crystalline silicon efficiency have of course been ongoing. SunPower, whose technology is a direct descendant of its IBC successor, announced its latest cell efficiency of 25% with 145μm thick n-type CZ silicon in its SunPower Maxeon Gen III production line. Testing a light-receiving area of 121cm2, this efficiency has been third-party verified by Fraunhofer ISE.

Sharp, with IBC cells and thin-film silicon cell production experience, managed to break its record by combining these two to create a back-contact HBC heterojunction cell to reach 25.1% as verified by Japan JET laboratory.

Panasonic outdid them both however, presenting their new efficiency record to a packed meeting hall full of people who had come to see their new technology during the last session on the Tuesday of the conference. Panasonic HIT cell combined with an IBC phase, using 150μm thick n-type CZ silicon to get an efficiency of 25.6% on a light-receiving area of 143.7cm2. This efficiency has been improved by a full 0.9% since 2013, when the company’s HIT cells were 24.7% efficient. This also marks 15 years of quiet efficiency improvements for monocrystalline silicon solar cells–up 0.6% from the previous year. The efficiency measurement was completed by a third-party laboratory, AIST, in Japan.

The new efficiency table from NREL. The blue lines show the latest crystalline silicon results from SunPower and Panasonic.

Although these technical achievements (IBC, HIT and combination of HIT and IBC) are still in the laboratory stage, they nevertheless provide the industry with an achievable benchmark–similar to the guidance that the PERL cell provides for the industry. The significance of these milestones in terms of where they fit into the crystalline silicon cell technology roadmap can not be ignored. An exchange with intoPV.com and a number of manufacturing companies last year was full of the discussion about choices for next-generation technologies: would IBC reign, or would HIT? The adoption of either one of these technologies will lead to much higher efficiencies compared to traditional cell structures. And–so far–manufactures can only achieve mass production using either HIT or IBC alone. However, it now appears that perhaps IBC and HIT may not be totally irreconcilable. Furthermore, the disadvantages of HIT, like absorption of front TCO and passivation layer, could be largely solved with the combination of the IBC structure. Will the two come together with crystalline silicon technology as the ultimate solution to it all? Only time will tell.

Finally, it is worth mentioning that SunPower and Panasonic have expressed confidence that their cell efficiency will increase to 26 percent, and this figure is what Dr. Swanson forecast in 2005. It appears that the efficiency of inter-company competition will also carry on.

© 2014 Solar Choice Pty Ltd

- Will thin film solar cells ever overtake crystalline silicon? - 6 October, 2014