SMA’s ‘Fuel Save’ controller solution offers effective regulation and management of PV‑diesel hybrid systems.

PV-diesel hybrid systems are often the most economic choice in remote areas where an electricity grid is unavailable or when the grid supply is insufficient to meet onsite electricity demand or reliability requirements. The technology can be attractive for commercial applications, such as mining, as well as public infrastructure projects – with large PV-diesel rollout programs announced or already operating by utilities in the Northern Territory, Queensland, Western Australia and South Australia.

PV-diesel mini-grids immediately face all of the challenges of the centralised grid when it comes to high levels of PV penetration – they’re at the front line and are therefore the breeding ground for new technology and solutions.

Increasing interest in a PV energy share has come as diesel fuel costs have increased in recent years, and the large market of diesel-only mini-grids in sunny areas that appear ripe for retrofit with PV. As storage costs make a strictly PV or wind mini-grid uneconomical, hybrid PV-diesel systems are a logical solution targeting fuel savings. While the biggest challenge is often the integration in small unstable grids, SMA’s Fuel Save solution connects and coordinates the diesel and PV components in such a way that the combined power output from the PV system and generator exactly match the instantaneous electricity demand in the system.

At times of high solar insolation, the diesel system output is reduced to maximise the use of generated photovoltaic energy and save fuel, whilst ensuring that the minimum diesel generator output is exceeded, avoiding additional wear. When the system load is significantly higher than what the PV system can provide, the Fuel Save controllers increase the output of the diesel generator to match the load.

The industrial set-up for a SMA Fuel Save system contains:

- A ‘Data Acquisition Board’: to analyse local load and grid conditions and relay information to the ‘PV Main Controller Module’;

- The ‘PV Main Controller Board’: to provide optimal PV power feed-in capacity as it evaluates current generator and load conditions;

- An SMA ‘Transformer Compact Station’: to meet onsite voltage requirements;

- SMA ‘Sunny String-Monitor’: to analyse individual PV system string output for precise PV yield monitoring; and

- The option of providing a ‘Sunny Central Storage’ system to store surplus photovoltaic energy in batteries. Battery storage power can compensate for fluctuations in load and irradiation, providing reserve power and facilitate optimised diesel generator operation.

The SMA Fuel Save system is targeted towards diesel systems in remote areas and/or industrial use. It is also applicable for micro-grid applications which contain a diesel generator in addition to a mixture of any number of other renewable energy sources.

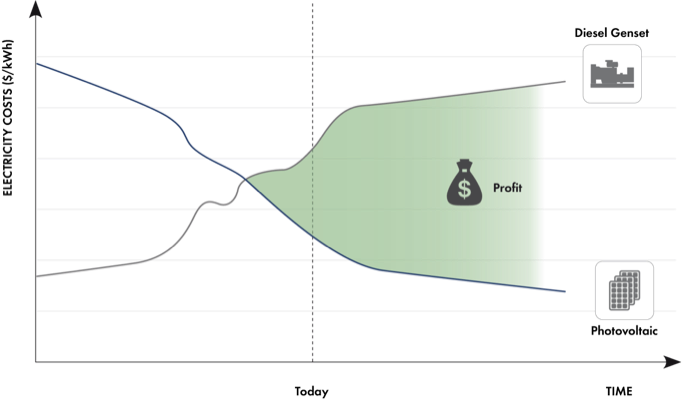

The overall cost of integrating PV into a diesel system is considerably less than the fuel costs it displaces, especially in remote areas. (Image Credit: SMA)

The LCOE for remote area gen sets is typically in the order of $0.3/kWh. Given that the LCOE of PV systems is currently floating in the range of $0.05–0.1/kWh, depending on insolation levels, the integration of PV and smart monitoring systems into remote area off-grid power supplies makes for a strong business case. With these clear economic benefits, it may be safe to say that nearly all diesel-powered sites across remote areas of Australia are targets for hybrid PV deployment. This is yet another example of how solar PV, renewables and storage can improve our existing energy systems.

Top Image Credit: SMA

© 2014 Solar Choice Pty Ltd